Automatic straightening production line

◆USES and features

The single-arm integral structure of the main engine has been processed. The straightening bench is equipped with movable straightening fulcrum, workpiece lifting and rotating devices, and two sides are equipped with transportation roller tables, which are connected with user transportation lines, with high automation. It has independent power mechanism and electrical system, and adopts button to centrally control the handle control system of auxiliary machine and main machine, which can realize fast down, slow down and fast return movement. Satisfied with the straightening process of bars, pipes and centrifugal cast pipes of nuclear energy superalloy with φ 50 ~ φ 300mm and length of 2000mm~12500mm. In order to find the straightening point quickly and put it in the straightening position, an automatic rotating device is installed on the workbench of the main machine of the production line. The automatic rotating device is provided with automatic lifting, falling, rotating, stopping and other actions. The control button is set in the hanging button station, which is convenient for operation. When the pressure head is close to the workpiece, it will automatically change to slow working speed to ensure that the workpiece is not damaged and the operation is safe. The left and right length of the main straightening bench can be designed and manufactured according to the user's requirements, and the two sides of the bench are provided with auxiliary conveyor roller tables, which are used to connect the main straightening bench with the roller tables of the user's workpiece transportation production line.

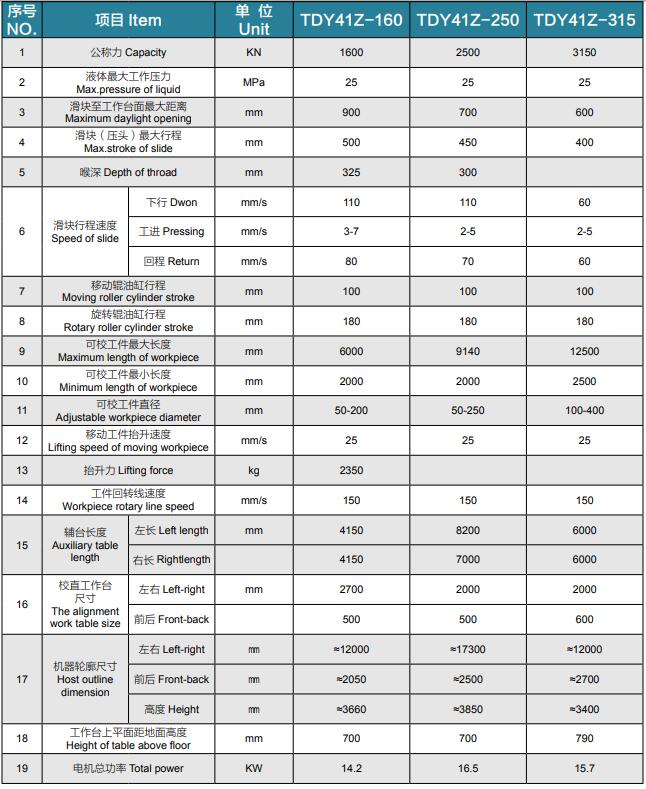

◆The main technical specifications

The single-arm integral structure of the main engine has been processed. The straightening bench is equipped with movable straightening fulcrum, workpiece lifting and rotating devices, and two sides are equipped with transportation roller tables, which are connected with user transportation lines, with high automation. It has independent power mechanism and electrical system, and adopts button to centrally control the handle control system of auxiliary machine and main machine, which can realize fast down, slow down and fast return movement. Satisfied with the straightening process of bars, pipes and centrifugal cast pipes of nuclear energy superalloy with φ 50 ~ φ 300mm and length of 2000mm~12500mm. In order to find the straightening point quickly and put it in the straightening position, an automatic rotating device is installed on the workbench of the main machine of the production line. The automatic rotating device is provided with automatic lifting, falling, rotating, stopping and other actions. The control button is set in the hanging button station, which is convenient for operation. When the pressure head is close to the workpiece, it will automatically change to slow working speed to ensure that the workpiece is not damaged and the operation is safe. The left and right length of the main straightening bench can be designed and manufactured according to the user's requirements, and the two sides of the bench are provided with auxiliary conveyor roller tables, which are used to connect the main straightening bench with the roller tables of the user's workpiece transportation production line.

◆The main technical specifications