TDY32 series aircraft panels and hot-pressing hydraulic pres

◆USES and features

This machine is suitable for the molding process of aircraft, automobiles and other interior parts, the pressing process of other plastic materials and the molding of covering parts. Can also be engaged in stamping, bending, flanging, sheet stretching, correction, press fitting, grinding wheel molding, cold extrusion metal parts molding, plastic products and powder products press molding. This machine has independent power mechanism and electrical system. With centralized control of buttons, three modes can be realized: adjustment, manual and semi-automatic. The working pressure, pressing speed, no-load fast descending and deceleration range of this machine can be adjusted according to the technological needs. Each process is divided into two kinds of process actions: constant pressure and fixed distance. The process action of constant pressure forming has the actions of holding pressure, delaying, automatic return and delayed automatic return after pressing. The main machine of this machine is rectangular, with novel and beautiful appearance. The power system adopts cartridge valve, which is simple and compact in structure and sensitive and reliable in action. The machine is also equipped with a foot switch, which can realize the cycle of semi-automatic process action.

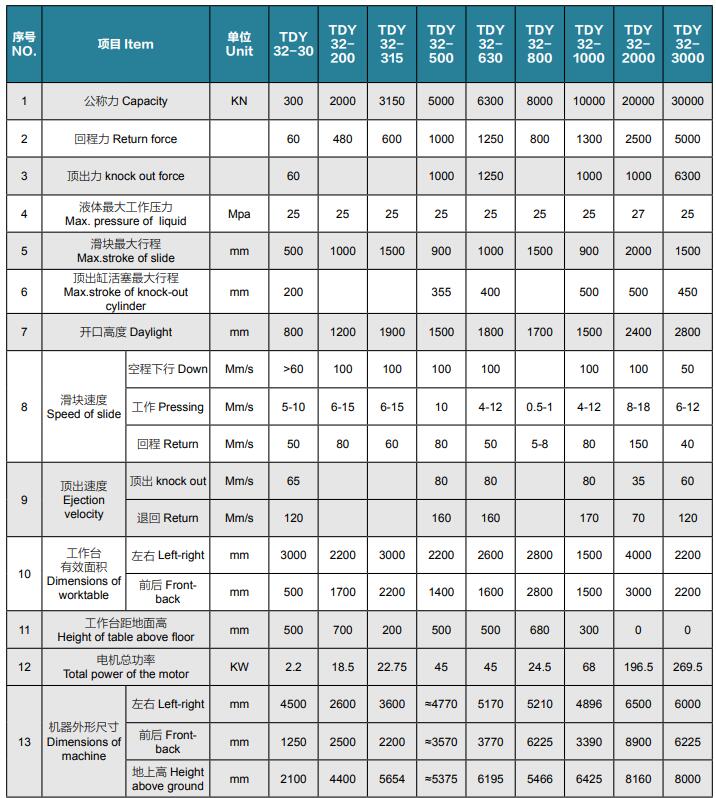

◆The main technical specifications

This machine is suitable for the molding process of aircraft, automobiles and other interior parts, the pressing process of other plastic materials and the molding of covering parts. Can also be engaged in stamping, bending, flanging, sheet stretching, correction, press fitting, grinding wheel molding, cold extrusion metal parts molding, plastic products and powder products press molding. This machine has independent power mechanism and electrical system. With centralized control of buttons, three modes can be realized: adjustment, manual and semi-automatic. The working pressure, pressing speed, no-load fast descending and deceleration range of this machine can be adjusted according to the technological needs. Each process is divided into two kinds of process actions: constant pressure and fixed distance. The process action of constant pressure forming has the actions of holding pressure, delaying, automatic return and delayed automatic return after pressing. The main machine of this machine is rectangular, with novel and beautiful appearance. The power system adopts cartridge valve, which is simple and compact in structure and sensitive and reliable in action. The machine is also equipped with a foot switch, which can realize the cycle of semi-automatic process action.

◆The main technical specifications